Fewer empty runs thanks to milk run systems – production with tugger trains

Key Facts

Customer

Manufacturer of car headlights, lighting and electronic components

Location

Germany

Industry

Electrics

Number of employees

36.000

Initial situation

- Transportation of small transport carriers, lattice boxes, Euro and industrial pallets

- Material delivery with front loaders

- Forklift operations: 30 operating hours per day

- Cost-intensive

- High traffic volume

- High level of dirt in the factory halls

- Safety risk for employees

- Narrow aisles (2.5 m) in production

Customer requirement

- Productivity increase

- Minimize empty runs

- Cost savings

- Increase security

- Smooth production supply with components and materials

LKE solution

- Streamlining production supply by means of a forklift-free tugger train system

- Platform wagon type X, KLT deck wagon, Cargo-Liner

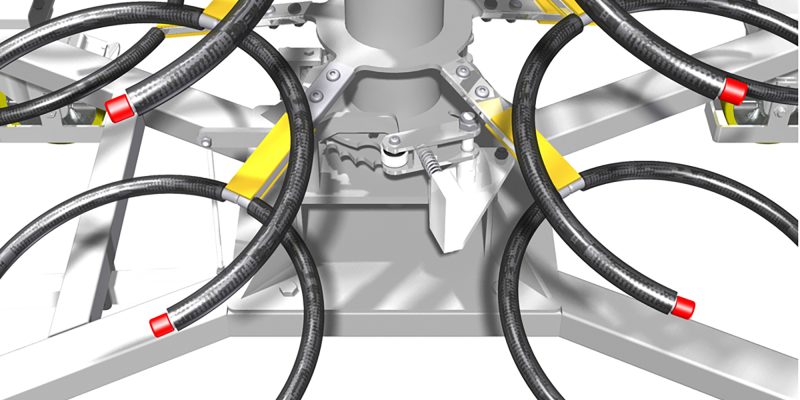

- Tugger train trolleys are equipped with the virtual LKE coupling and drawbar system for optimum directional stability in the narrow aisles

- 4 tugger trains on 5 routes in operation at the same time while the next transport trains are waiting

- Tractor: 4 tractors

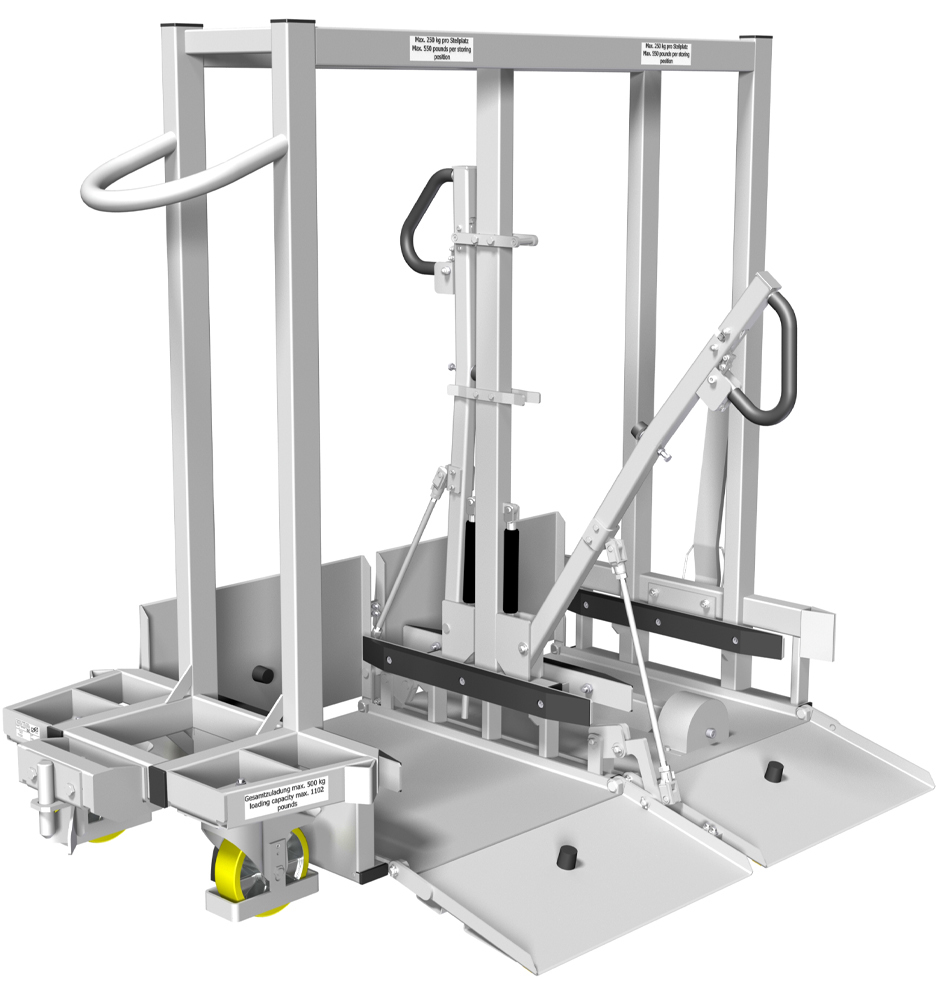

Cab car Cargo Liner SP2

- Pick-up of KLT containers and frame trolleys

- Central hand lever

- Two parking spaces

- Loading and unloading on both sides

- Indoor and outdoor

- Overrun protection on all castors

- Virtual clutch and drawbar system

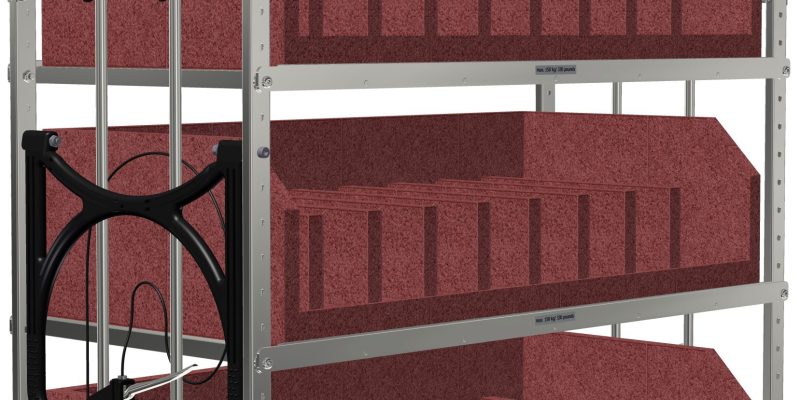

KLT wagon 600 E4

Small transport carrier trolley for order picking

- Three sloping shelves

- 100 kg load capacity per level

- Overrun protection on all castors

- Central locking device with simple foot control

- Pull handle with handbrake

- Virtual clutch and drawbar system

Platform trolley type X

of pallet cages, Euro and industrial pallets

- Stackable

- Loading and unloading on both sides

- Self-locking drawbar

- Ergonomic handle

- Overrun protection on all castors

- Virtual clutch and drawbar system

Result

- Elimination of pallet truck use

- Increased productivity, increased delivery frequency > Consistent capacity utilization > 2,000 containers are retrieved and installed every day

- Time savings thanks to precise delivery to the employee

- Empty runs reduced by 15% – distribution of full containers and simultaneous collection of empty containers

- Cost savings

- Track-true handling in the aisles, some of which are 2.5 m wide

- Any wagons can be uncoupled from the route train

- Traffic volume minimized

- More security

- Space saving in the aisles of the production halls of 600 pallet spaces