170 fewer journeys per day

Key Facts

Customer

ZF Friedrichshafen

Location

Friedrichshafen

Industry

Drive and chassis components

Number of employees

157.549

Initial situation

- Production delivery by front loader

- Transportation of steel boxes

- Limited spatial conditions

- Replenishment by one material dealer on each of six assembly lines

- Waiting times on the assembly line

- Inventory differences / incorrect planning

- High traffic volume

- High safety risk for employees

Customer requirement

- Two frame trolley parking spaces

- Front stackers are to be gradually removed from production

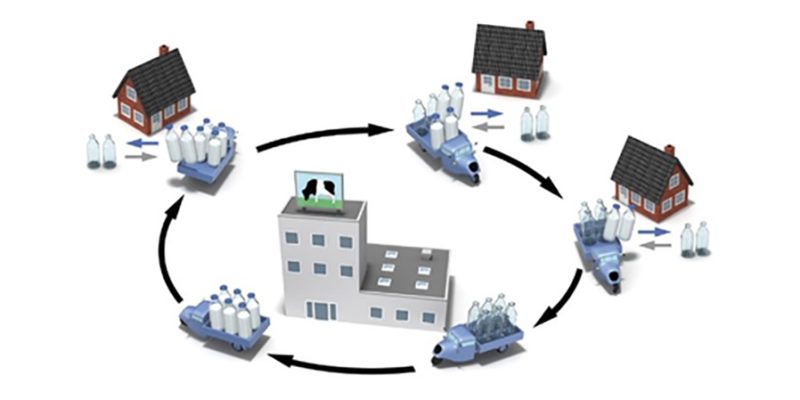

- Effective tugger train system for material delivery

- Due to the limited space available: High directional stability, loading and unloading on both sides, use of no more than two trailers at the same time

LKE solution

- Virtual LKE clutch and drawbar system for optimum directional stability

- Production supply by means of a forklift-free tugger train system

- Cargo-Liner cab trolley in special dimensions > Can be integrated into the existing customer system

- Platform trolley type X > Supplement for transporting customer-specific steel crates in a tugger train

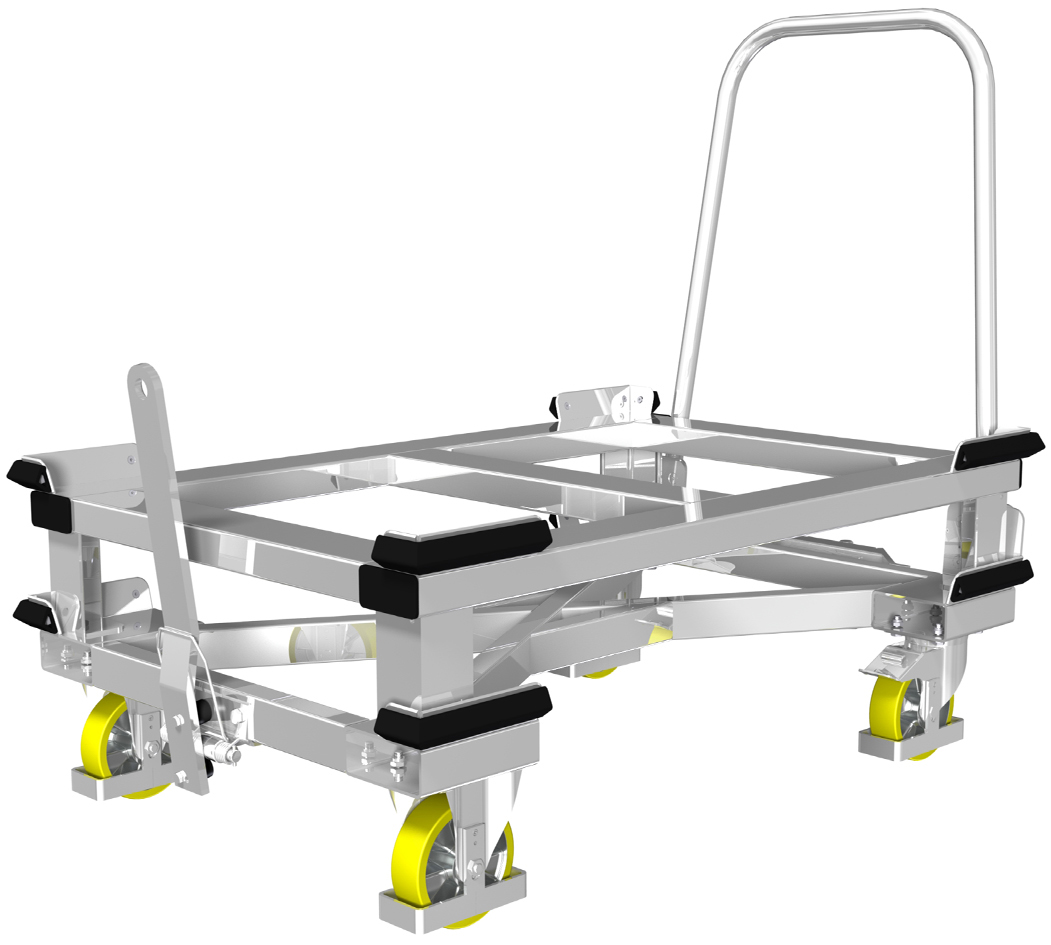

Cab car Cargo Liner SP2

Individual solution for transporting frame trolleys with customized steel boxes

- Two parking spaces

- Central hand lever

- Loading and unloading on both sides

- Secured drawbar

- Virtual clutch and drawbar system

- Overrun protection on all castors

Platform trolley type X

Individual solution for transporting customer-specific steel boxes

- Two floors

- Stackable

- Loading and unloading on both sides

- Secured drawbar

- Virtual clutch and drawbar system

- Overrun protection on all castors

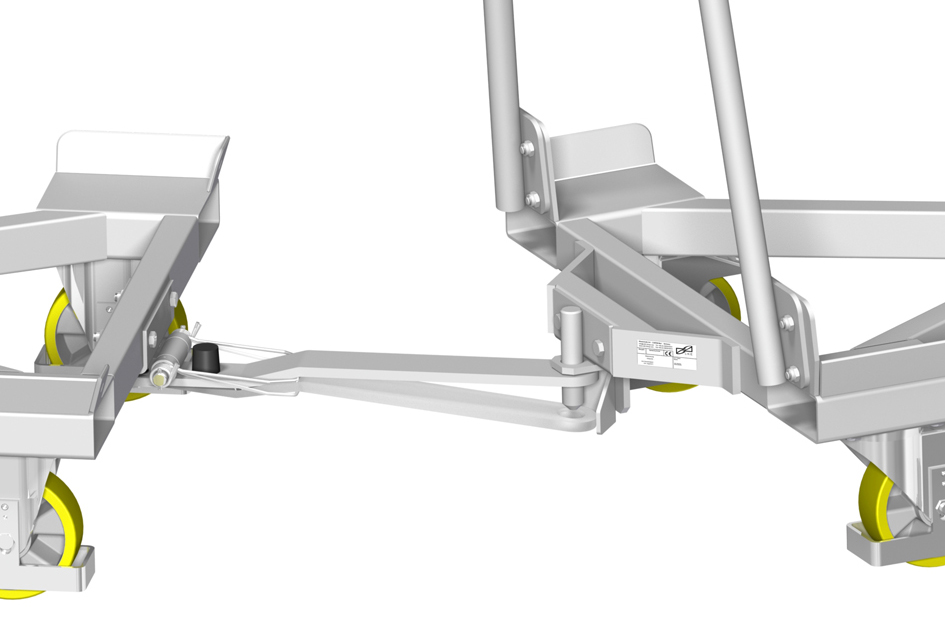

Virtual clutch and drawbar system

For easy handling

- Optimum directional stability

- Simple foot operation

- Self-locking drawbar ensures that the trailers do not uncouple when connected

Result

- Optimum directional stability thanks to the use of the LKE coupling and drawbar system

- 170 fewer journeys thanks to the use of Cargo-Liners

- Cost reduction of 70,000 euros / year

- Inventory differences eliminated

- Reliable and timely delivery to the assembly stations

- Precise material planning

- Time saving for material delivery

- Reduced traffic volume

- More security

- Space saving