WHAT ARE ROUTE TRAINS?

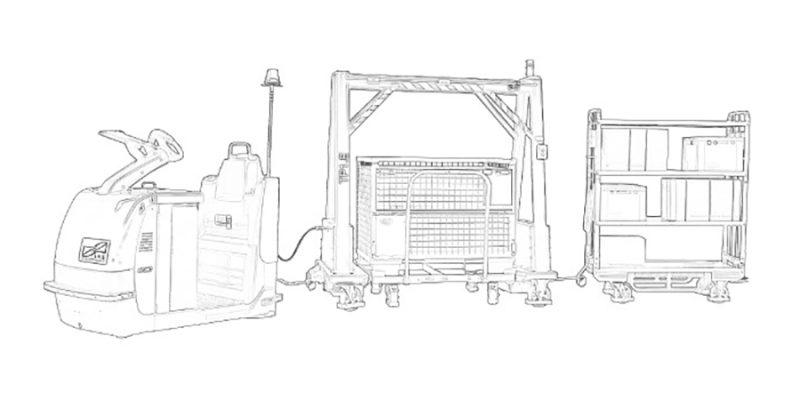

Tugger trains are an internal transport solution that optimizes the transport of materials within a company. This type of transportation significantly supports just-in-time and just-in-sequence production. The tractors move trolley arrangements through the company, which can be loaded individually according to internal requirements. Materials are transported efficiently to or from processing machines or assembly stations, for example, replacing the need for forklift trucks.

Advantages of

Route trains

- Minimization of empty runs

- Different materials can be used together at the same time

be transported - Faster and safer compared to transportation by forklift truck

- With the virtual clutch and drawbar system, the

Train with excellent directional stability - Low product costs

- Savings on forklift trucks and personnel costs

- Continuous throughput time optimization

Tugger train vs. forklift truck:

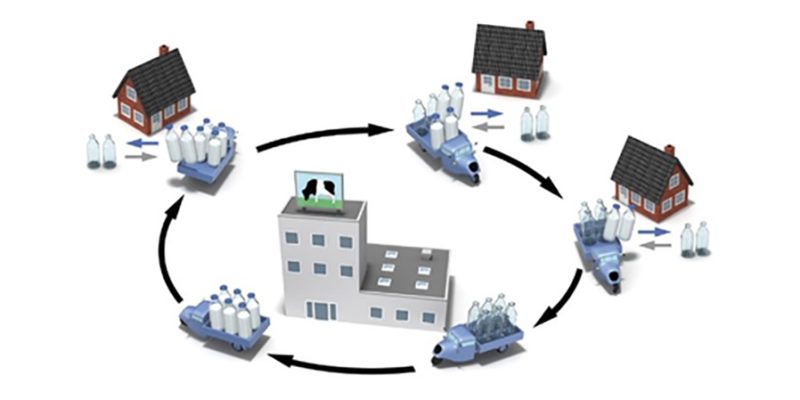

Milkrun principle

The advantages are obvious: the tugger train supplies several stations in a single pass. With the forklift truck, on the other hand, each station has to be approached individually. It is easy to calculate that this leads to increased traffic volumes and significantly more distance driven – which in turn leads to increased wear and tear on the equipment and an increased risk of accidents.

Various requirements can be met with the tugger train using the flexibly attached trolleys: In addition to different unit loads (pallets, Euroboxes, tons and much more), the trains can be put together individually for each round trip. During delivery, the next train is already being loaded in the warehouse.

The tractor unit starts the next round immediately after returning to the warehouse via the LKE quick coupling. The various compatible trailers are also significantly cheaper to purchase – and to maintain anyway. With up to 5 trolleys, delivery remains as flexible as possible and can be adapted spontaneously to changing needs.

Optimum directional stability with LKE steering systems

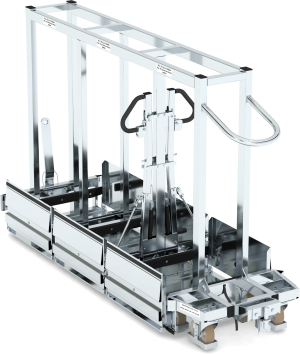

LKE has developed a trailer system for material supply with the tugger train, on which the various common standard load carriers, such as Euro pallets or Euro boxes, can be transported.

To ensure that the trailers stay on track, they can be equipped with the virtual coupling/drawbar system.

Ergonomic & efficient:

Loading and unloading on both sides

The product solutions shown can be transported together and can be loaded and unloaded on both sides of the tugger train. This allows the train system to adapt efficiently to your operating requirements.

We plan your tugger train system

Would your company also like to benefit from the use of tugger trains? We would be happy to work with you to plan your tugger train solution: contact us and we will be happy to support you from the initial idea to the tugger train in operation.

Our top sellers for tugger trains:

-

Cargo-Liner SP3

Art.-Nr: 566-1000-430-SP3 Cargo-Liner3 Stellplätze, Grundfläche 2375x750mm, Nutzfläche pro Stellplatz 430x638mm

-

-

KLT-Wagen 600 E1 VKD

Art.-Nr: 263-5001 Shelf trolleyZuladung Grundboden 300kg, 2 Lenk- & 2 Bockrollen, zentraler Feststellhebel, Zuggriff

-

-

-

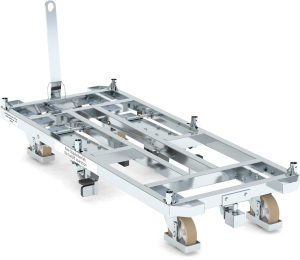

Plattformwagen Typ X.2 Euro VKD

Art.-Nr: 471-9002-A Floor rollerEuromaß, virtuelles Kupplungs-/ Deichselsystem

-