Special solution for a manufacturer of large electrical appliances

Key Facts

Customer

Manufacturer of large electrical appliances

Location

Germany

Industry

Industrial manufacturing

Employees

62.000 (2021)

Material supply by tugger train – fewer forklifts

Initial situation

- Assembly line with different heights

- Use of forklift trucks in the assembly area

- Routes and paths too long

- Not efficient

- Material supply requires too much space

Customer requirement

- Conversion from forklift delivery to a tugger train system

- Efficient transportation of components

- Ergonomics

- Space saving

LKE solution

- Production supply by means of a forklift-free tugger train system

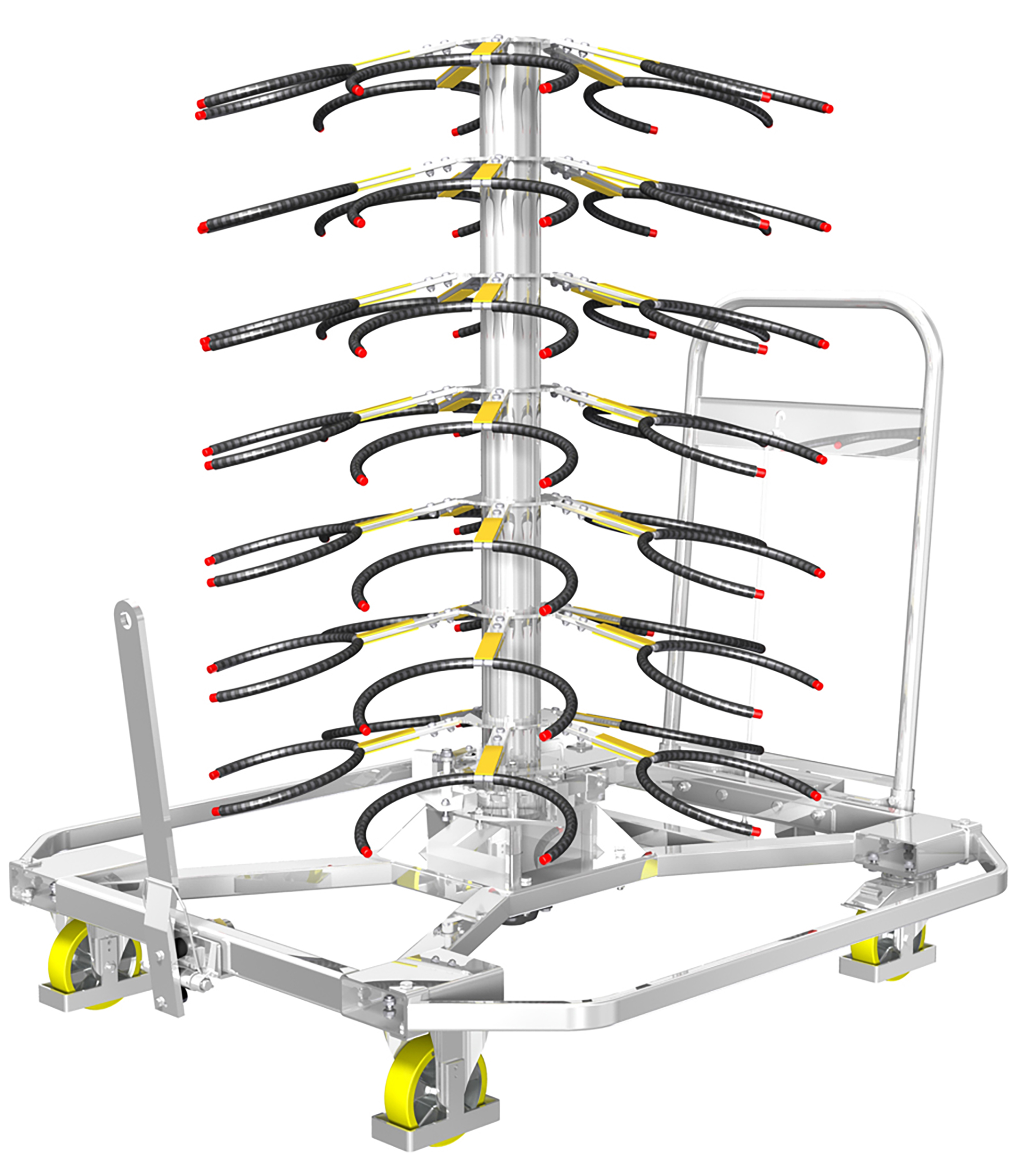

- Platform trolley type X with frame and superstructure

- Transport of 35 product components on seven levels per platform trolley

- Frame can be locked by means of a lever on the handle – no turning while driving

- Release the locking mechanism at the mounting location, suitable removal position can be set

- Virtual LKE clutch and drawbar system for true-to-track handling

LKE product

- Type X platform trailer with superstructure

- Individual solution for transportation

- of washing machine windows

- Frame with seven levels

- Ergonomic handle

- Loading and unloading on both sides

- Self-locking drawbar

- Virtual clutch and drawbar system

- Overrun protection on all castors

Virtual clutch and drawbar system for easy handling

- Optimum directional stability

- Simple foot operation

- Self-locking drawbar ensures that the trailers do not uncouple when combined

Platform trolley type X.1 Euro with special superstructure

Technical data:

Load capacity: max. 1000 kg

Usable area 1225 x 825 mm

incl. virtual clutch/drawbar system

Special structure